Centre of Metal Recycling in Legnica

Center of Metal Recycling

Division in Legnica

Professional waste management

We develop and implement non-ferrous metal recovery technologies. We specialize in the development of metal recycling technologies from waste materials of various origins.

Our technologies include both thermal and chemical processes.

We offer innovative recovery solutions:

- lead

- tin

- antimony

- tungsten

- molibden

- nickel

- vanadium

- cobalt

- zinc

- copper

We also have our own technologies for recovering metals from used catalysts.

We offer joint development in the areas of:

- management of waste in various physical forms in order to recover base, refractory and precious metals

- service processing of materials into raw lead, lead alloys, oxides, salts and acids of molybdenum, tungsten, zinc, vanadium, nickel and cobalt and concentrates of precious metals, in particular palladium, platinum, gold, silver and rhodium

- collection and management of waste acidic and alkaline solutions

- supply of abrasive materials and mineral water conditioners

We produce professional PolGrit™ abrasive blast cleaning abrasive.

The abrasive does not contain acids, salts or water-soluble ingredients.

OFFER

Products and services

PolGrit™

Abrasive materials

Hydrocleanit

Mineral Water Conditioners

Waste treatment services

Acidic and alkaline solutions

organization

Implementation and production departments

Metallurgical Production Department

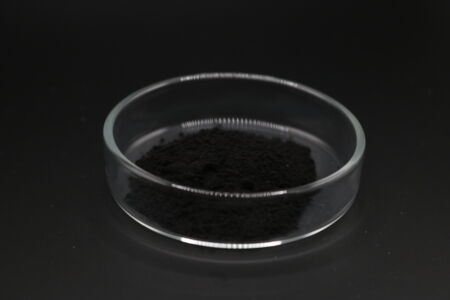

We produce PbSb alloys with a minimum Pb content of 99% and 0.5-6% Sb.

We provide smelting services

- scrap,

- dross,

- Dust

- and other lead-bearing materials.

- Dross and lead concentrates

- dross and lead-antimony concentrates

- cable scrap Pb

- other materials containing, among others. 40% Pb

- battery scrap

- lead alloy with Pb content min. 99%

We are looking for secondary raw materials, semi-finished products and waste from the non-ferrous metals industry and more

Contact

Head of Department: Przemysław Sydor

phone: +48 535 269 222

Chemical Recycling Department

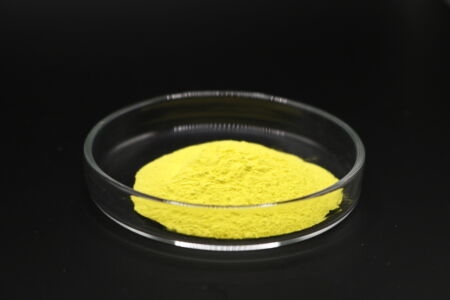

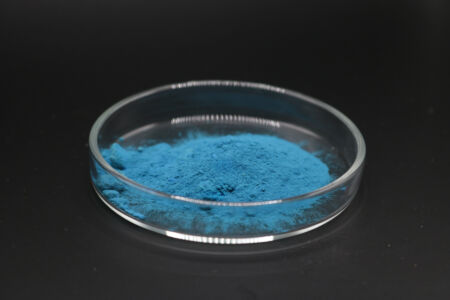

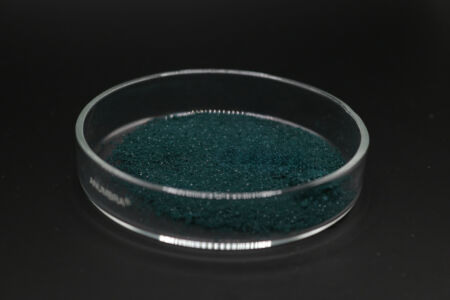

The Chemical Recycling Department produces:

- tungstic acid

- molybdic acid

- tungsten trioxide

- sodium tungstate

- calcium tungstate

- vanadium pentoxide

- precious metal concentrates

- copper sulfate

- copper acetate and copper hydroxide

- precious metal concentrates (powders)

- zinc chloride in solution and crystalline form

Contact

Head of Department: Ewa Szydłowska-Braszak

+48 76 745 03 67

ewa.szydlowska-braszak@imn.lukasiewicz.gov.pl

Abrasive Materials Production Department

We are a manufacturer of professional abrasives and mineral water conditioners.

PolGrit™

Abrasive for blast cleaning with the trade name Polgrit abrasive is a synthetic and amorphous material in which SiO2 is bound in the form of complex silicon compounds, the free silica content does not exceed 1%.

The abrasive does not contain acids, salts or water-soluble ingredients.

HYDROCLEANITE

in Hydrocleanite, calcium carbonate and magnesium oxide determine the high chemical activity of the deposit in relation to contaminants present in water. Hydrocleanite is in the form of granules, which are used as layers of filter material in the bed of open and pressure filters.

The use of Hydrocleanite does not require any additional equipment. Hydrocleanite replaces the middle layers of filter beds.

Contact

Head of Department: Justyna Byczkowicz

+48 76 757 67 45

Science to business

Metal processing technologies

for over 14 years

Own, unique technologies

Tungsten

Primary raw materials

- shelit

- wolframite

Secondary raw materials

- alloy WFeNi, WCu, WCoC, WMo, WCr, etc.

- dross

- dusts

- powders

- tungsten carbide

PRODUCTS

- Tungsten trioxide

- Tungstic acid

- Sodium tungstate

- Calcium tungstate

- Ammonium paratungstate

Refractory metals

Primary raw materials

- Pb-V ore

Secondary raw materials

- scrap

- dusts

- powders

- dross

- solutions

- spent catalytic converters

PRODUCTS

- Molybdic acid

- Vanadium pentoxide

- Nickel oxide

- Nickel carbonate

Science to business

Cooperation with industry

We implement the Circular Economy policy

Value proposition

- production based solely on waste raw materials

- proprietary recovery technologies

- experimental production installations

- R&D and implementation works supported by the experience of the main R&D center of the Polish non-ferrous metals industry

- technological solutions awarded in invention competitions in Poland and abroad, including: Innova – Barcelona, IPITEX – Bangkok, MTP – Poznań

We produce chemical compounds of non-ferrous metals with the required parameters

Chemical production

- zinc

- copper

- tungsten

- molybdenum

- vanadium

- cobalt

- nickel

- precious metals

Pyro processes

- lead

- tin

- tungsten

- antimony

- bismuth

Mechanical separation

- abrasives

- water filtration beds

Management Systems

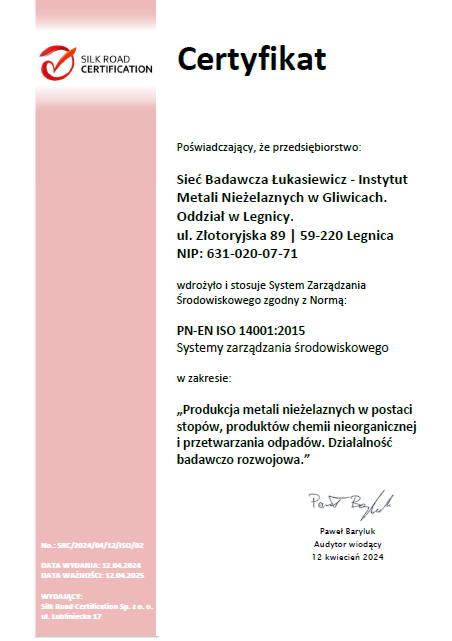

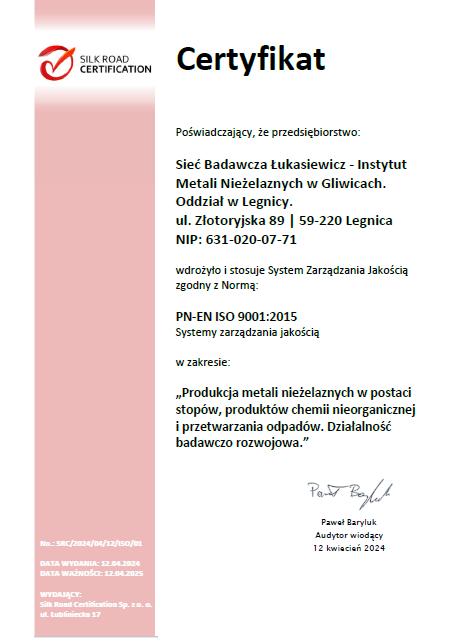

Implemented management systems

We manage our business in accordance with globally recognized standards.

We have implemented business management procedures in accordance with the following standards:

- ISO 9001:2015 Quality Management Systems and

- PN-EN ISO 14001:2015

Environmental Management Systems

in the field of “Production of non-ferrous metals in the form of alloys, inorganic chemical products and waste processing. Research and development activities”

Infrastructure

Gallery

Download

Documents for download

Contact us