OFFER

Hydrocleanit treats surface water, groundwater, soft and acidic water, and acidic wastewater

The use of Hydrocleanit does not require any additional devices

Water purification processes are accompanied by enrichment of water with calcium and magnesium

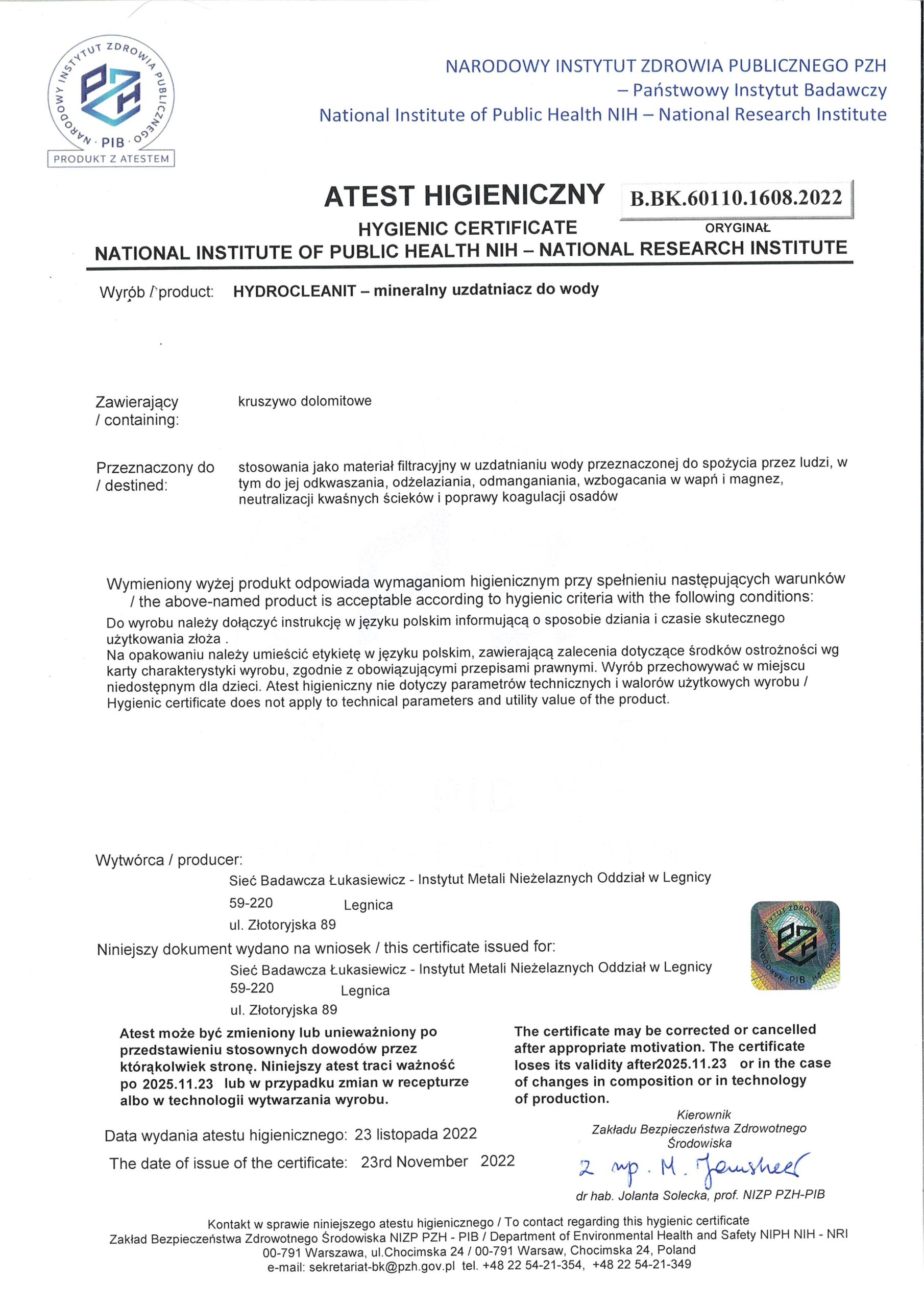

Hydrocleanit

Mineral Water Conditioners

We are a manufacturer of mineral water conditioners Hydrocleanit.

Hydrocleanit replaces the power switch of the filter beds.

.Hydrocleanit replaces the power switch of the filter beds

enriching water with calcium and magnesium.

The use of Hydrocleanit does not require any additional devices.

The main tasks of the Hydrocleanit conditioner include:

- deacidification

- iron removal,

- water manganese removal,

- sorption of organic pollutants.

In Hydrocleanite calcium carbonate and magnesium oxide determine the high chemical activity of the deposit in relation to pollutants Occurring in water. Hydrocleanit has the form of granules, which It is used as layers of filter material in open filter bed i pressure filters.

Hydrocleanite the middle layers of filter beds

The application Hydrocleanit does not requires any additional equipment.

Due to its physical and chemical properties, the Hydrocleanit bed is widely used in the processes of treatment and treatment surface water< wpml_nbsp > groundwater, soft water, acidic water and acidic water Wastewater. To the main processes w which applied is Hydrocleanit belong: deacidification, iron removal, manganese removal water and sorption of organic pollutants . In addition the processes treatment water are accompanied by the enrichment of water with calcium and magnesium

An effective method of iron removal is the use of raw water filtration through the Hydrocleanit bed. Raw water filtration through the Hydrocleanit bed causes:

- alkalizację wody: wzrost twardości i zasadowości wody spowodowany jest wiązaniem agresywnego dwutlenku węgla i kwaśnych produktów reakcji i wytworzeniem wodorowęglanów wapnia i magnezu

- water aeration: effective binding of aggressive carbon dioxide aerates water in pressurized systems..

Water removal is a process necessary in the treatment and purification of groundwater, infiltration water and, less frequently, surface water.

How do the iron removal processes work?

Iron, depending on the content of organic substances, oxygen and carbon dioxide in the water, may be present in water in dissolved form, colloidal or as suspension. The most common form of iron is iron soluble compounds divalent Fe(II). Methods for removing water used in the iron(II) feeding process Information about the oxidation state of Fe(III), where iron is located, Fe(OH)3, hardly soluble in water and then sedimentation and filtration. Due to the iron sulfate that may be present in water aggressive CO2, water alkalinization is required by adding lime, carbonate or hydroxide sodium. Hydrolysis of iron compounds occurs most effectively at a pH of no more than 8.0. At pH>10 there is an increase in the solubility of Fe(OH)3 caused by the transfer of hydroxide

iron into the Fe(OH)-4 anion.

The efficiency of iron removal is determined by the following water parameters

- pH,

- concentration of free carbon dioxide and dissolved oxygen and

- alkalinity of water

Factors that interfere with the water removal process,include

- reduced organic substances

- ammonium nitrogen

- methane and

- hydrogen sulfide

However, it is advisable to additionally aerate the water in order to obtain the required amount of dissolved oxygen: for pH 6-8, 0.5-0.9 mg O2/ 1 mg Fe (II) is needed. Oxidation of iron Fe(II) to Fe(III) to produce Fe(OH)3.

Hydrocleanit

✔Eliminates the need to use chemical iron oxidants

✔ Eliminates the need to carry out the sedimentation process before filtration

✔Effectively removes iron from water

Application of the hydrocleanit deposit with simultaneous use water aerationeliminates the need to use chemical iron oxidants such as chlorine ozone or potassium permanganate. Additionally, Hydrocleanit eliminates the need to carry out the sedimentation process before filtration

– Fe(OH)3 flocs are retained in the Hydrocleanit bed and are washed out of it during cyclic bed rinsing. Condition: the iron concentration in the purified water is less than or equal to 10 g Fe/m3

Wpracowane złoże Hydrocleanit (pokryte tlenkami żelaza i manganu) pozwala na skuteczne odżelazianie wody przy pH 6.8. The manganese oxides covering the bed act as an oxidant towards Fe(II) Filtration through a Hydrocleanit bed allows you to destabilize colored complexes formed on the basis of humic substances and iron. As a result of filtration, organic pollutants react with the components of the deposit: calcium and magnesium. An important parameter is the Ca/Mg ratio in the purified water: if it is less than 4.4, it indicates contamination przyłączają wapń, a w uzdatnianej wodzie następuje wzrost stężenia magnezu. Gdy Ca/ Mg > 4,4 wówczas zanieczyszczenia they react with magnesium, which increases calcium in filtered water

How is water removed from manganese?

The essence of the water removal process is the oxidation of Mn(II) to Mn(IV) and the precipitation of manganese in the form of MnO2*xH2O. Oxidation of manganese is usually achieved by aerating the water and dosing strong oxidants into the water (potassium permanganate, chlorine, ozone), because the oxygen present in the water after aeration is often in too small amounts and prevents full oxidation of manganese. Purified water after the oxidation process should be filtered, preferably through filtered beds, and then subjected to disinfection. An important parameter in the manganese removal process is the water pH, which is 9.5 for the manganese oxidation reaction with oxygen.

The water removal process takes place effectively during filtration of the treated water on the Hydrocleanit bed with simultaneous aeration of the water. Water filtration using the Hydrocleanit bed increases the alkalinity of the water, which determines the effectiveness of the process

water removal. During filtration, acidic reaction products are removed (e.g. aggressive CO2, H2SO4), accompanied by water aeration (in pressure systems)

The Hydrocleanit filter bed, in contact with purified water containing manganese ions, is activated by covering the grains with manganese dioxide oxidation reaction catalyst. The deposit developed in this way causes the oxidation of divalent manganese to trivalent (Mn2O3) and tetravalent (Mn3O4(OH)2). The precipitated MnO2*H2O shell catalyzes oxidation of subsequent amounts of Mn(II) flowing into the Hydrocleanit deposit with purified water. Removal of manganese during evaporated bed filtration occurs at >6,8.

Why is it worth using Hydrocleanit?

✔Filtration through the Hydrocleanit bed eliminates the need to use chemicals that are manganese oxidants

✔Simultaneous water aeration

How is water deacidified?

The water deacidification process aims to remove aggressive carbon dioxide from the water, which makes the water acidic reaction. Water deacidification is necessary for groundwater and infiltration water. The procedure can be performed through physical or chemical methods.

Physical methods involve water aeration achieved in pressurized or open devices the so-called aerators equipped with air and water mixers

Chemical methods involve dosing into water quicklime or hydrated lime, sometimes soda ash or sodium hydroxide. In the chemical method it is necessary to equip the installation with cumbersome devices, e.g. for preparing and dosing lime

Why is it worth using Hydrocleanit?

A simple and economical solution is to filter raw water through a Hydrocleanit bed

The magnesium oxide and calcium carbonate contained in the bed react with aggressive carbon dioxide to form magnesium bicarbonate and calcium bicarbonate according to the reaction:

MgO + 2CO2 + H2O = Mg(HCO3)2 CaCO3 + CO2 + H2O = Ca(HCO3)2. As a result of the reaction, the alkalinity and hardness of the water increase. The increase in overall hardness depends on time of water contact with the Hydrocleanit bed. The longer it is, the greater the increase in overall hardness

- for a speed of 5 m/h the increase is 0.085 degree of stiffness. / mg CO2

- for a speed of 15 m/h the increase is 0.057 deg./mg CO2

Using too low water filtration speeds can cause the pH to rise>8,3 and precipitation in carbonate bed calcium. The increase in water alkalinity depends on the amount of bound CO2 and is approximately: 1.13 g CaCO3/ 1 g CO2 As a result of aggressive CO2 binding, the Hydrocleanit deposit is consumed, which is 1.30 g Hydrocleanit / 1 g CO2.

Contact us

Contact

Abrasive Materials Production Department

in Głogów

street Żukowicka 1

67-200 Głogów

Located in Copper Smelter “Głogów” (entry no. 6)