Laboratory

Laboratory of Physical Metallurgy and Chemical Analysis

Metal science and chemical analyses

Laboratory of Physical Metallurgy and Chemical Analysis deals with research and design of materials in the field of structure and properties of aluminum and magnesium alloys in terms of new technologies, with particular emphasis on the circular economy (Circular Economy).

Experience and modern infrastructure

Many years of experience of laboratory employees in the analysis of light metal alloys using modern equipment allows for a deep understanding of the selection of materials and optimization of production processes at various stages of production/manufacturing.

Accredited since 2002

The laboratory operates an accredited metallurgical and chemical analysis laboratory certified by the Polish Center for Accreditation (no. AB 394).

The laboratory conducts international projects under the following programs: EIT RAW MATERIALS, HORIZON 2020, CORNET.

Accreditation

Accreditation scope

Domain and tested objects

- Chemical tests of metals

- Mechanical tests, metallographic tests of products and construction materials, including:

metals, composites and ceramics - Testing the physical properties of products and construction materials, including metals and composites

- Non-destructive testing of coatings on metals and metal alloys

Standards

Standards and reference documents

We perform tests in accordance with the standards:

- PB-7 6th edition

- PB-5 5th edition

- ISO 10074:2021(E) PN-EN ISO 7784-2:2016-05

- PN-EN ISO 9227:2017-06

- PN-EN ISO 2360:2017-10

- PN-EN ISO 6507-1:2018-05

- PN-EN ISO 6506-1:2014-12

- PN-EN ISO 6892-1:2020-05

- Method A

- Method B

- PB-K 6th edition

- PB-A 4th edition

- PB-O 7th edition

- PB-E 6th edition

- PB-SK 5th edition

- PB-R1 5th edition

- PB-R2 7th edition

- PB-N 5th edition

- PB-As 5th edition

Offer

Our offer

The tests are performed in accordance with the requirements of current standards, own procedures and the requirements of the quality system at the accredited Laboratory (PCA certificate no. AB 394).

Chemical analyses

-

Analysis of the chemical composition of aluminum and magnesium alloys using optical emission spectrometry

-

Measuring the hydrogen value in metals using high-temperature extraction

- Composition analysis by atomic absorption spectrometry

Structure research using

-

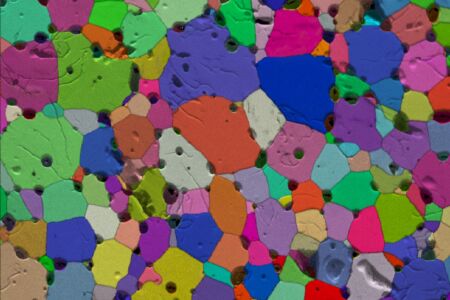

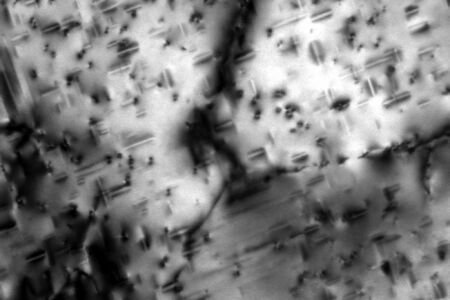

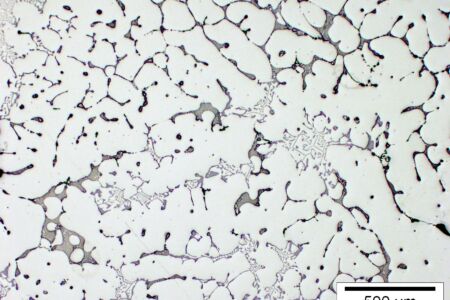

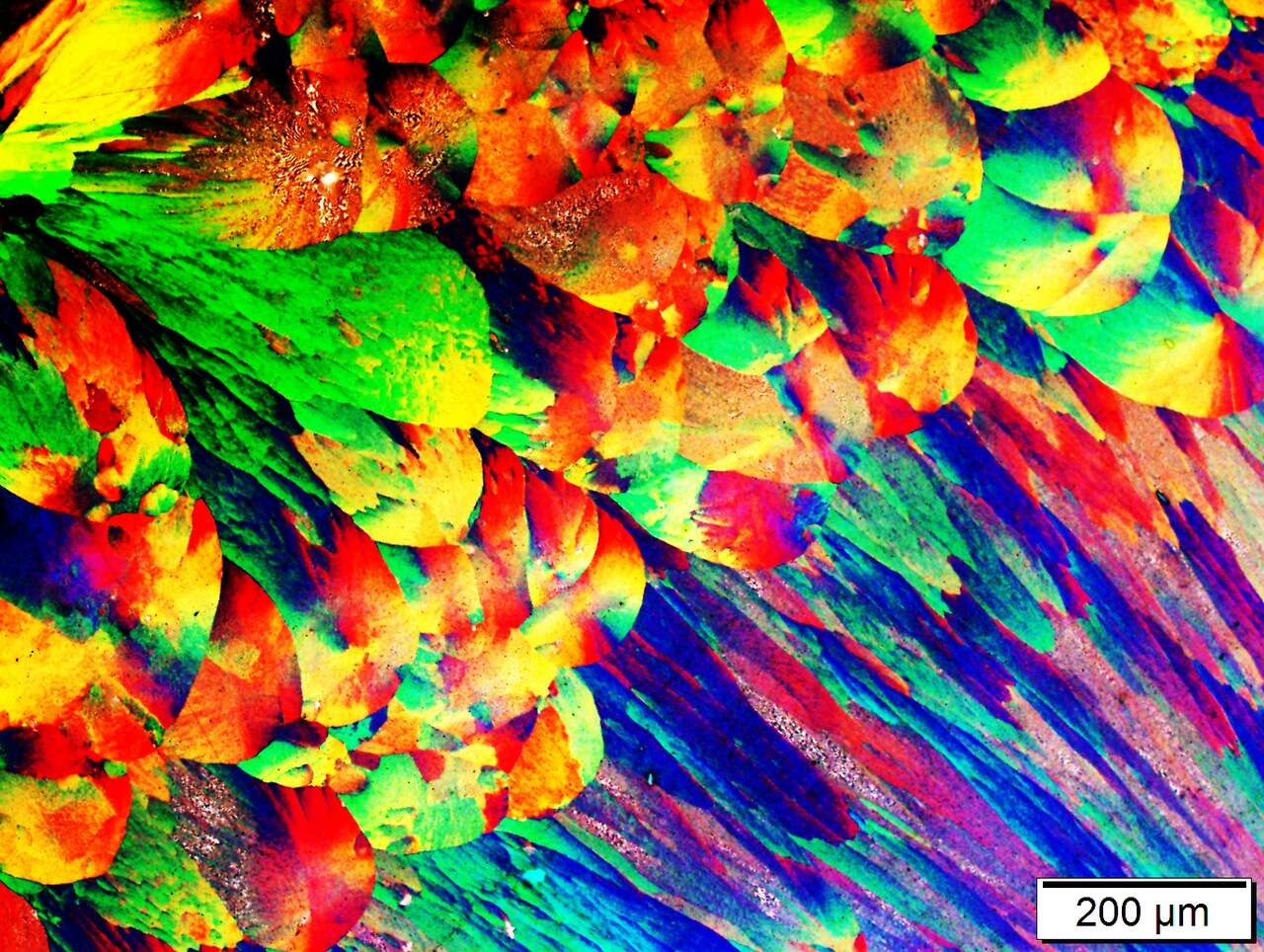

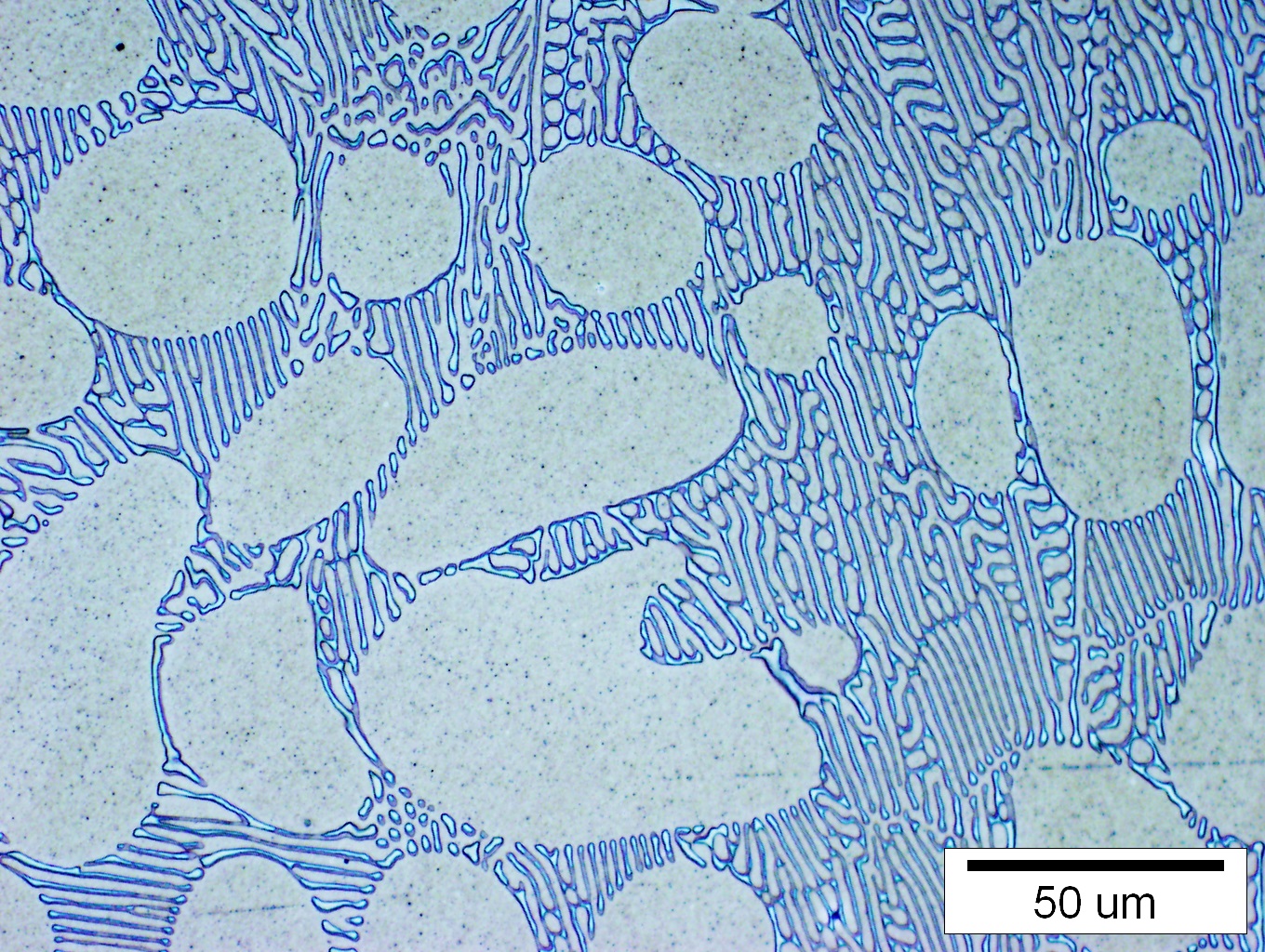

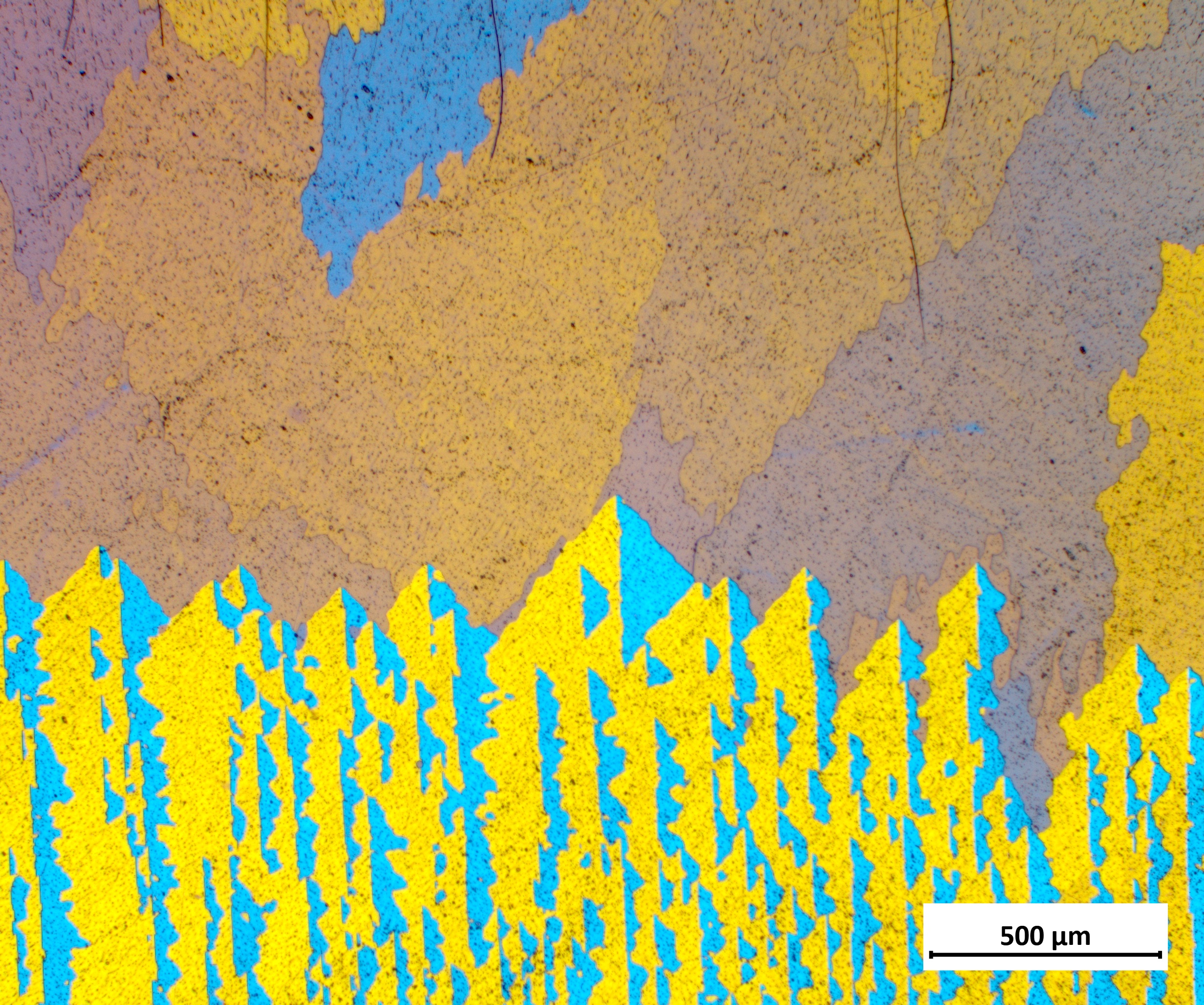

Light microscopy

-

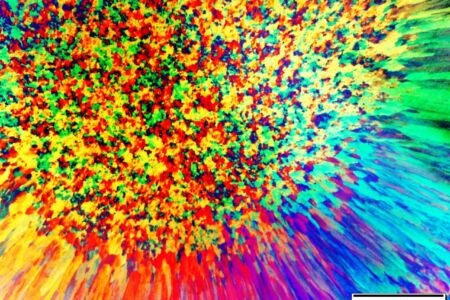

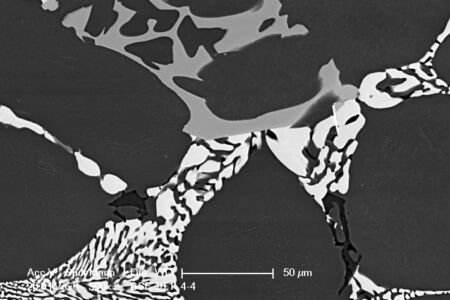

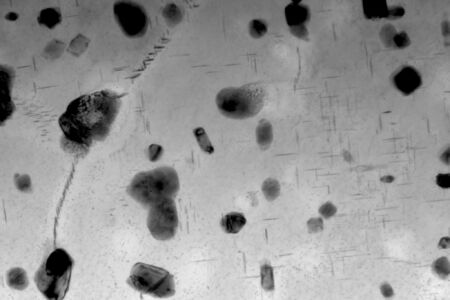

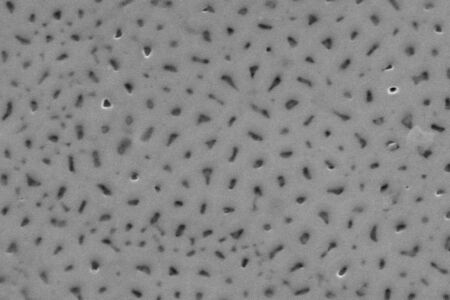

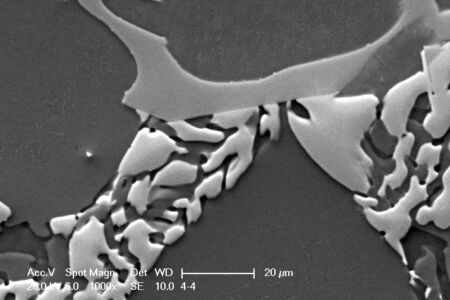

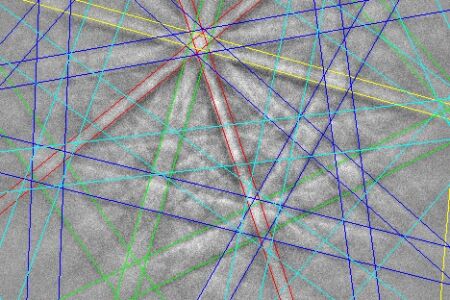

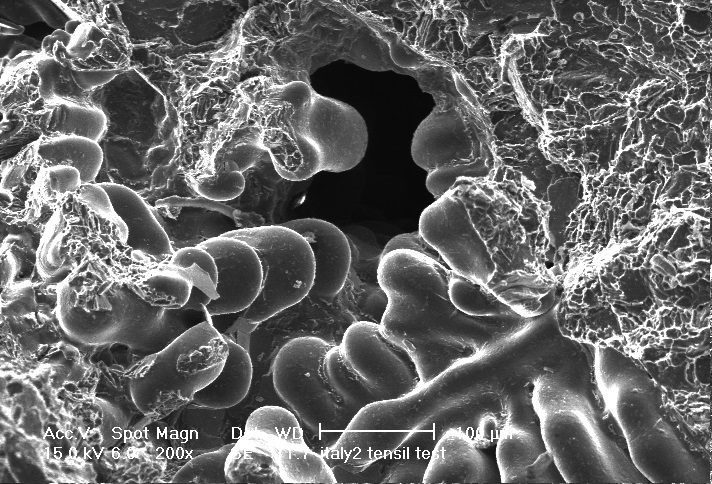

High-resolution scanning electron microscopy (SEM-HR), which includes micro-area X-ray chemical analysis (EDS) and crystallographic analysis of grain orientation and phase analysis (EBSD + ChiScan)

-

Transmission electron microscopy (TEM) with X-ray chemical analysis in micro-areas (HAADF-STEM and EDS)

-

Computer image analysis that allows for quantitative assessment and measurement of the size of grains, phases and impurities from sediments above the Prefil Footprinter® filter

X-ray tests

-

Qualitative and quantitative phase analysis

-

Measurement of residual stresses and retained austenite content by X-ray diffraction

Mechanical properties tests

-

Measurement of mechanical properties of metals in static tensile and compression tests at temperatures from -170oC to 1200oC

-

Three-point bending test

-

Khan test (tear test)

-

Pipe expansion test

-

Cupping test

-

Customized technological tests

-

Hardness measurements using the Vickers, Brinell, Rockwell and Knoop methods

RD

RD scope

Circular Economy

Development of technologies for producing new and innovative materials based on light metals, with particular emphasis on circular economy

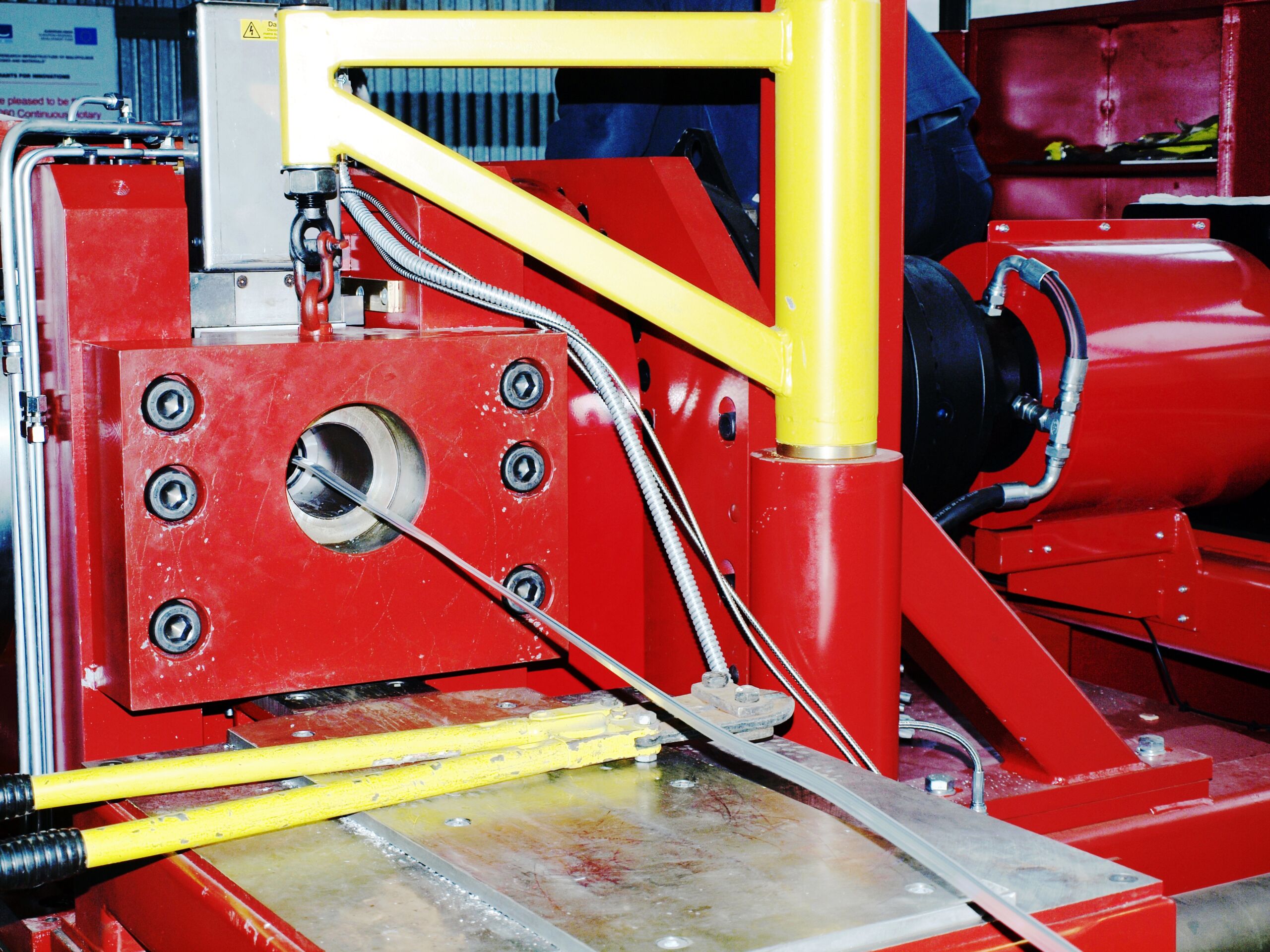

- Development of a recycling technology based on crushed aluminum scrap by plastic processing using the CRE (Conform®) continuous wheel extrusion method.

Components for industry

-

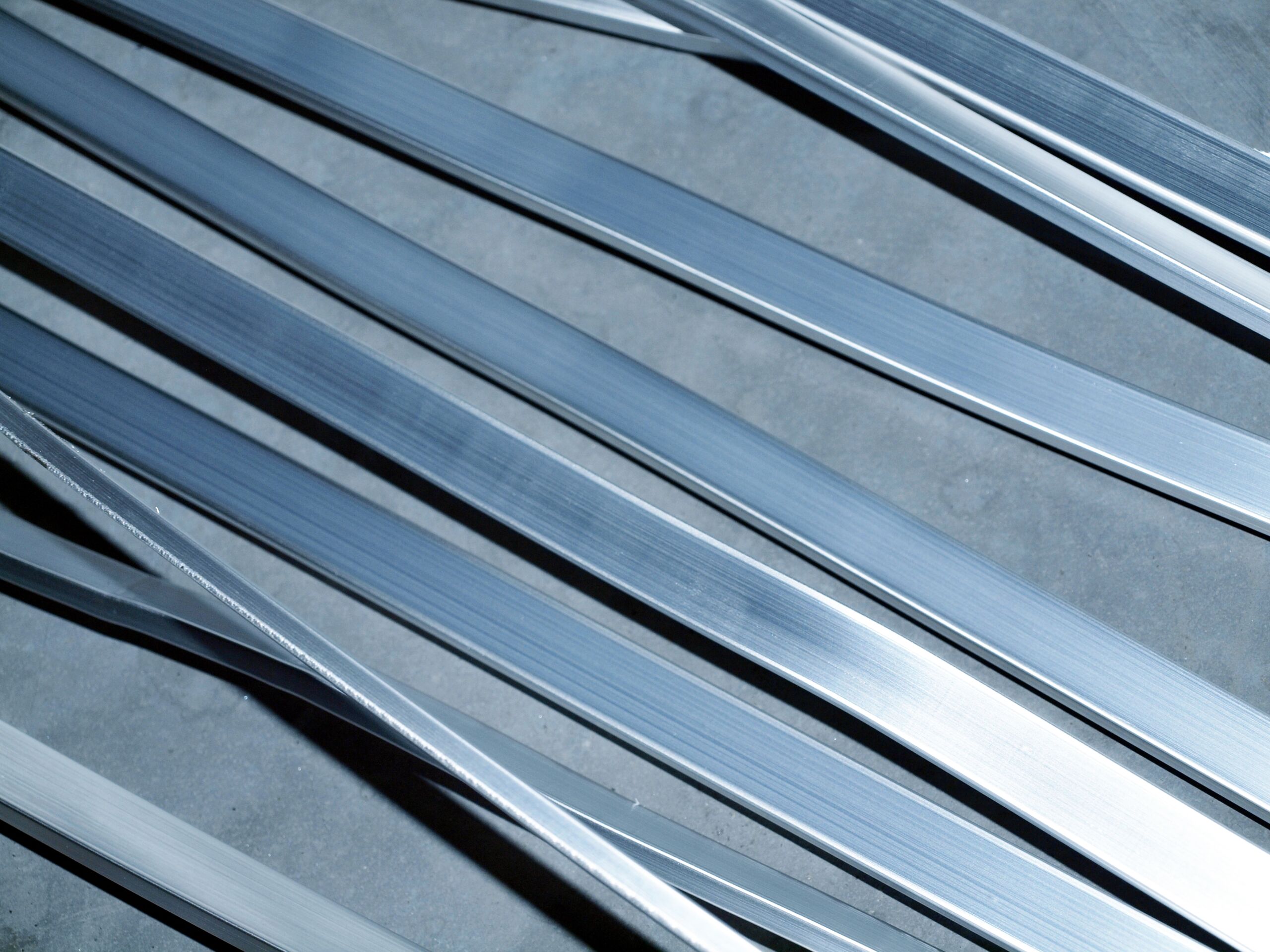

Development of technologies for manufacturing shape elements, such as machine parts or components both using traditional and non-standard methods for the transport industry

Plastic treatment

-

Development of heat treatment technologies for light metal alloys – ingot homogenization parameters, supersaturation and aging parameters

-

Development of cold and hot rolling technologies for aluminum alloys in order to obtain appropriate operational parameters (rolling technologies for deep-drawn sheets, bimetallic and clad sheets)

-

Development of a technology for CRE (Conform®) continuous wheel extrusion of profiles made of aluminum and magnesium alloys using solid and loose materials

Laboratory

Contact

Łukasiewicz – Research Networs

Laboratory of Physical Metallurgy and Chemical Analysis

Piłsudskiego 19 street

32-050 Skawina, Poland

Head of Laboratory: Wojciech Szymański, PhD