Laboratory

Chemical Power Sources Testing Laboratory

Tests of batteries and cells

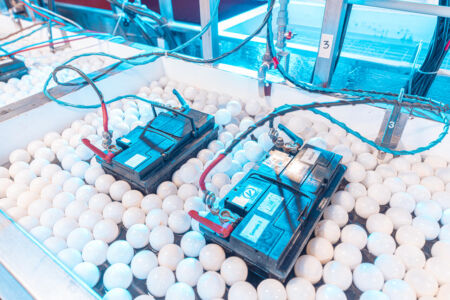

At the laboratory we do electrical, mechanical, environmental and safety (included handling and transport) tests for all types of batteries and cells.

Battery tests are performed according to international and national standards, technical conditions, safety criteria or Client’s specification.

Precision and expertise

We provide our expertise and state-of-art equipment to do demanding tests with due dilligence, accuracy and safety.

We are an independent entity. We cooperate both with global manufacturers of chemical power sources and small and medium enterprises.

Accreditation

Accreditation scope

Domain and tested objects

- Electrical tests of electric objects

- Physical test of electric objects

- Mechanical tests of electric objects

- Fire tests of electric objects

Primary cells

- Leakage and deformation resistance

- Electrical tests

- Measured parameters:

- current

- voltage

- Scope:

- current 2 mA ÷ 1500 A

- voltage (0,1 ÷ 800) V

- Measured parameters:

- Testing method that involves discharging batteries or cells with constant current or constant voltage

- Electrical parameters:

- BMS performance

- discharge

Lead-acid batteries and cells

- Dimensions. Scope: (0,5 ÷ 630) mm

- Max. voltage at no load. Scope: (0,1 ÷ 100) V

- Discharge. Scope: 0,05 mA to 1500 A

- Leakage and deformation resistance

- Electrical tests

- Measured parameters:

- current

- voltage

- Scope:

- current 2 mA ÷ 1500 A

- voltage (0,1 ÷ 800) V

- Measured parameters:

- Testing method that involves discharging batteries or cells with constant current or constant voltage

- Electrical parameters:

- BMS performance

- discharge

Alcaline batteries and cells

- Electrical tests

- Measured parameters:

- current

- voltage

- Scope:

- current 0,05 mA ÷ 1500 A

- voltage (0,1 ÷ 100) V

- Measured parameters:

- Testing method that involves battery charging with constant current or constant voltage and next discharging with constant current or constant voltage or constant power

- Electrical parameters:

- max. acceptable discharge current

- cyclability (cycle lifespan)

- corrosion resistance

- capacity (discharge)

- short circuit current and internal resistance

- reserve operation possibility (charge)

- charge acceptance after deep discharge

- discharge at high current

- charge acceptability

- cranking aptitude

- self-discharge

- water use

Primary batteries and cells

Secondary batteries and cells

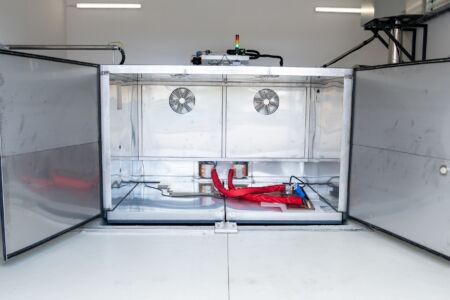

- Thermal tests

- Resistance to:

- temperature cycling

- low temperature

- high temperature

- thermal stress

- Scope: (-70 do + 180)ºC, method: tests in climatic chamber

- Resistance to:

- Humidity tests

- Humidity resistance

- scope: (20 ÷ 98)% of humidity

- Method: tests in a climatic chamber

- Humidity resistance

- Pressure tests

- Low pressure resistance

- Scope: (2 ÷ 20) kPa

- Method: tests in pressure chamber

- Low pressure resistance

Secondary lead-acid batteries and cells

Secondary alcaline batteries and cells

- Dimensions. Scope: (0,5 ÷ 630) mm

- Insulation resistance. Scope: (1 ÷ 100) MΩ

- External short-circuit resistance

- Mechanical tests:

- free fall

- fire propagation test

- Direct testing method

REESS

- Standard cycle

- Temperature cycling

- Fire resistance

- External short-circuit resistance

- Overcharge resistance

- Deep discharge resistance

- Dimensions. Scope: (0,5 ÷ 630) mm

- Max. voltage at no load. Scope: (0,1 ÷ 100) V

- Discharge. Scope: 0,05 mA to 1500 A

Standards

Standards and reference documents

Lithium systems:

- Manual of tests and critera UN 38.3

- Regulation 100 UNECE

- Regulation 136 UNECE

- PN-EN 61960-3

- PN-EN 62619

- PN-EN 50604-1

- PN-EN 60086-4

- PN-EN 61959

- PN-EN 62133-2

- PN-EN 62281

- PN-EN 62660-1

- PN-EN 62660-2

- PN-EN 62660-3

- PN-EN 62813

- PN-EN IEC 62928

- and other documents, standards or manufacturer’s specifications

Lead-acid systems:

- PN-EN 50342-1

- PN-EN 50342-2

- PN-EN 50342-3

- PN-EN 50342-4

- PN-EN 50342-5

- PN-EN 50342-6

- PN-EN 50342-7

- PN-EN 60254-1

- PN-EN 60254-2

- PN-EN 60896-11

- PN-EN 60896-21

- PN-EN 60896-22

- PN-EN 60952-1

- PN-EN 60952-2

- PN-EN 60952-3

- PN-EN 61044

- PN-EN 61056-1

- PN-EN 61056-2

- PN-EN 62485-3

- PN-EN-83013

- PN-EN-83016

- and other documents, standards or manufacturer’s specifications

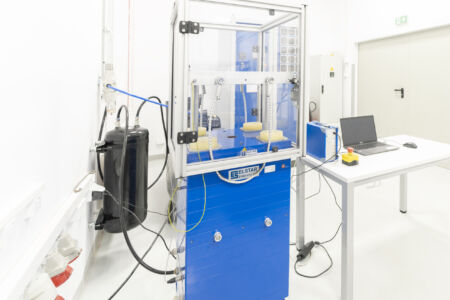

State-of-the-art equipment and testing systems

Equipment

- Electrical testers

- Short circuit tester

- Climatic chambers

- Pressure chamber

- Vibration tester L

- Vibration tester M

- Mechanical integrity tester

- Nail penetration tester and crash tester

- Fire propagation testing system

- Impact tester

- Temperature baths

Offer

Offer

Electrical tests:

- capacity (discharge)

- cyclability (cycle lifespan)

- short circuit current and internal resistance

- max. acceptable discharge current

- overcharge

- extended charging resistance

- cranking aptitude

- cyclability at set DoD (ex. 50% DoD, 17,5% DoD)

- electrolyte retention

- water use

- corrosion resistance

- dynamic charge acceptance

- connection quality

- capacity retention after long shelf-life

- reserve operation possibility

Climatic tests:

- temperature cycling

- charging and discharging at different temperatures (-70°C +180°C, 5°C/min)

- altitude simulation (10 mbar)

- humidity resistance (10% – 98%)

- thermal stresses in a chamber equipped with a lift

- corrosion resistance

Mechanical tests:

- sine and random vibrations

- impacts

- crush, impact, penetration

- free fall

Safety tests:

- improper installation

- leakage and deformation resistance

- fire propagation test

- external short circuit resistance

- overcharge resistance

- BMS performance

- single failure test

- forced discharge

- fire resistance test

Download:

Offer

Chemical Power Soures

Testing Laboratory

Our assets

Accreditation since 1997

Competences:

The Laboratory’s staff consists of highly qualified and experienced employees. We have measuring equipment that guarantees the highest quality of services provided. Analyzing market needs, we systematically expand the scope of our activities. We monitor the industry in terms of changing standards and legal regulations. Our clients can be sure that cooperation with us is based on the latest and reliable knowledge.

We are open to changes:

To meet the expectations of our clients, we adapt the scope of tests to individual needs, we perform tests based on standards or other documents indicated by the client, including tests not covered by the scope of accreditation.

Improvement:

By listening to our clients’ suggestions, we want to improve the range of services we offer. That’s why your opinions are so important to us. We will be grateful if you complete a short customer satisfaction survey, which will take no more than 2 minutes.

Laboratory

Contact

Łukasiewicz Research Network – Institute of Non-Ferrous Metals

Chemical Power Sources Testing Laboratory

ul. Forteczna 12

61-362 Poznań

Head: Kamil Frączek

Jędrzej Kałużny