Centre of Functional Materials

About us

Centre of Functional Materials

Our activity

The Functional Materials Center conducts work on technologies for manufacturing innovative new generation materials, in particular:

- new materials and technologies for power electronics, energy, transport and medicine

- soft magnetic nanocomposites for high-frequency high-power processing

- amorphous and nanocrystalline filter chokes for improving the quality of electrical energy

- amorphous and nanocrystalline materials for use in special current transformers for electricity meters, energy and transport

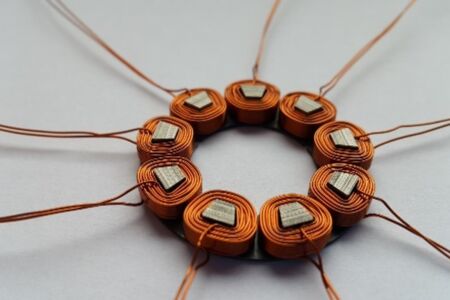

- amorphous and nanocrystalline stators for high-speed electric motors and heart assist pumps

- technology for manufacturing hard binders, in particular for the refrigeration and automotive industries

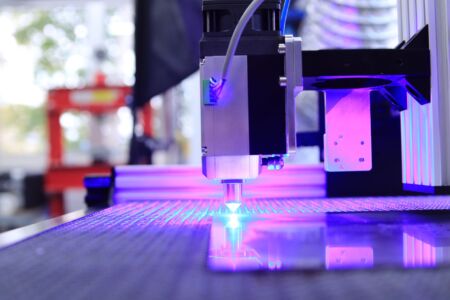

- additive technologies – new solutions for power electronics

- magnetocaloric materials for magnetic cooling technology

- technology for manufacturing metal, ceramic and polymer composites and bio-composites for industrial and medical needs

- manufacturing of contact rivets

- absorbers of electromagnetic radiation

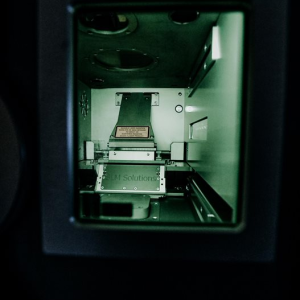

Modern equipment

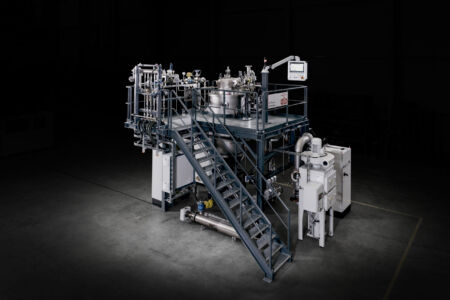

Materials Center functional has modern equipment for the synthesis of materials, as well as for their full characterization, starting from the structure, physical, magnetic and thermal properties, up to determining purely application parameters. The research and technological base consists of devices in which the latest technical thought has been used, and therefore they are often unique on a national scale.

Production of advanced materials

We have the ability to produce materials using various techniques, including: induction and arc melting, milling and melt-spinning casting. In order to verify the correctness of the melting process, the obtained alloys are subjected to chemical composition analysis using a four-channel X-ray microprobe equipped with ebsd and eds spectrometers (electron backscatter diffraction and energy dispersive spectroscopy).

Technical and technological consulting

We also offer consulting services in the field of construction of technological devices and technology for casting amorphous tapes using the rapid cooling method and manufacturing cores from these tapes using appropriately selected heat or thermomagnetic treatment. We also provide material expertise, particularly for magnetically soft materials.

Production

As part of our low-volume production, we offer:

- base alloys and thin strips cast using the melt-spinning method with a variety of chemical compositions

- amorphous and nanocrystalline cores with properties that make them suitable for various applications

- amorphous binders based on Cu and Ni

- contact rivets

Services

- measurements of magnetic properties of magnetically soft and hard materials

- metallurgical services (casting alloys with a given chemical composition, casting amorphous strips)

- laser cutting and engraving of plastics

- making metallographic microsections

- measurements of magnetic properties of magnetically soft and hard materials

- research and expertise on the developed topics

R&D

Laboratories

Laboratory of Advanced Magnetic Materials

The Laboratory of Advanced Magnetic Materials conducts research, including primarily the development of techniques for measuring the magnetic properties of magnetic materials, including nanocomposites, nanocrystalline and amorphous magnetically soft materials, and magnetically hard materials.

Laboratory of Manufacturing Functional, Structural and Biomaterials

R&D

Research Groups

Research Group of Amorphous and Nanocrystalline Magnetically Soft Materials

Contact

Leader: Łukasz Hawełek, PhD

+48 32 23 80 484

lukasz.hawelek@imn.lukasiewicz.gov.pl

Research group of Polymer Materials and Biomaterials

Contact

Leader: Andrzej Hudecki, PhD

+48 32 23 80 484,

andrzej.hudecki@imn.lukasiewicz.gov.pl

Research Group of Casting Techniques, Gas Spraying and 3D Printing

Contact

Leader: Marcin Karpiński, PhD

+48 32 23 80 240

marcin.karpinski@imn.lukasiewicz.gov.pl

Manufacturing

Manufacture

Small Volume Production Section

Contact

Leader: Marcin Karpiński, PhD

+48 32 23 80 240

marcin.karpinski@imn.lukasiewicz.gov.pl

Implemented projects

Cooperation with the industry

In cooperation with industry, we have implemented projects whose results have a real impact on the business results of our partners.

Some of them are:

- achieving the production phase and continuous sale of Ni-based hard binders manufactured on the basis of the technology developed at the Institute using ultra-fast cooling of the liquid alloy on the surface of a rotating cylinder.

- developing and implementing the technology for manufacturing nanocrystalline magnetically soft alloys with increased magnetic induction as a replacement for silicon steel.

- launching the production of transformers for induction heaters.

- launching the serial production of static converters for electric locomotives using a new generation of transformers made of amorphous materials.

- launching the production of SPS-100MN-24.5 power supplies using cores made of magnetically soft materials.

- DC/AC converters with a power of up to 2kW operating at a frequency of 50kHz and supplied with a voltage of 220V using cores made of magnetically soft materials.

- developing and implementing the technology for manufacturing amorphous magnetically soft cores as a replacement for classic P50 alloys. launching the production of measuring current transformers based on nanocrystalline cores with accuracy classes 0.2 0.2S 0.5 0.5S.

- development and implementation of the technology for manufacturing nanocrystalline cores as replacements for classic P80 type materials.

MAterials

To downloand

Oferta || Offer

materiały amorficzne i nanokrystaliczne, rdzenie magnetycznie miękkie, luty twarde, aparatura

PL || EN

Our expertise

presentation of research areas, technologies and their application to industries and businesses

EN

3D and SLM technology

alloy design and SLM technology development for innovation-driven industries

EN

Contact us